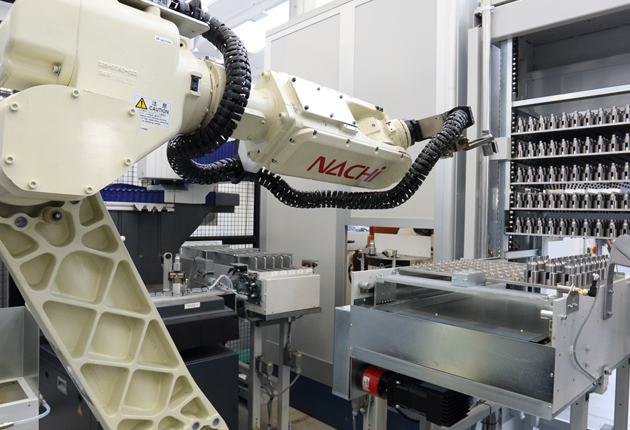

The single machines are connected to robots in line in order to create a production path dedicated to the most complex processes. We have automatic lines for induction hardening, 3D machines, plus robotic palletisation and automatic packaging machines that together assure complete in line control, with major time and cost savings.