At Gi Di Meccanica we can carry out dimensional checks on production directly in-house, quickly and without bringing in third-party laboratories (other than for accredited instrument calibration purposes).

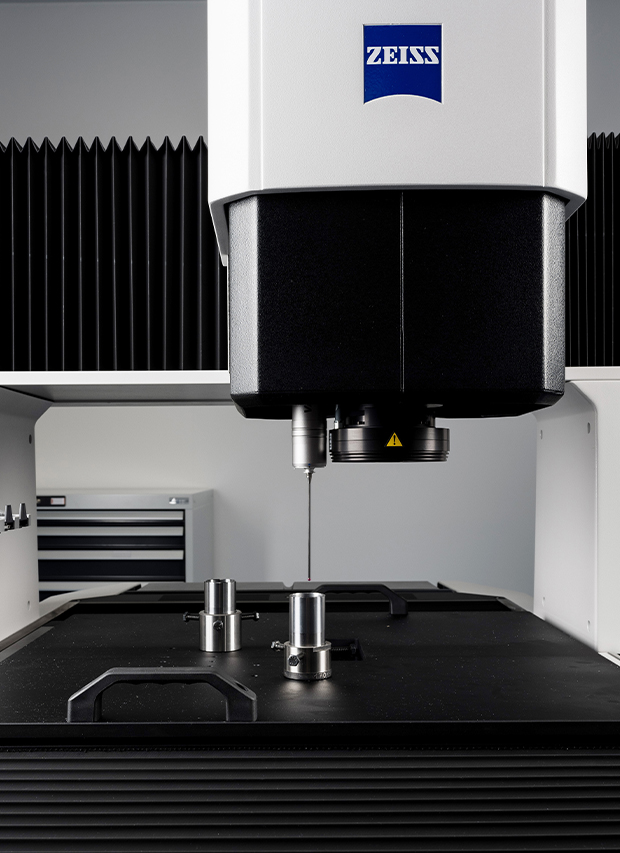

Our metrology laboratory, which we created in 2013 and completely upgraded in 2022, when it was also relocated, is air conditioned to maintain a constant temperature of 20°C to minimise thermal expansion related errors that can arise if measuring instruments are subjected to temperature gradients.

The strategic decision to implement this service inside our organisation is a plus from the client’s standpoint because not only do we guarantee that the product supplied complies precisely with contract specifications, we can also issue all the necessary test certificates, thereby streamlining processes and saving time.

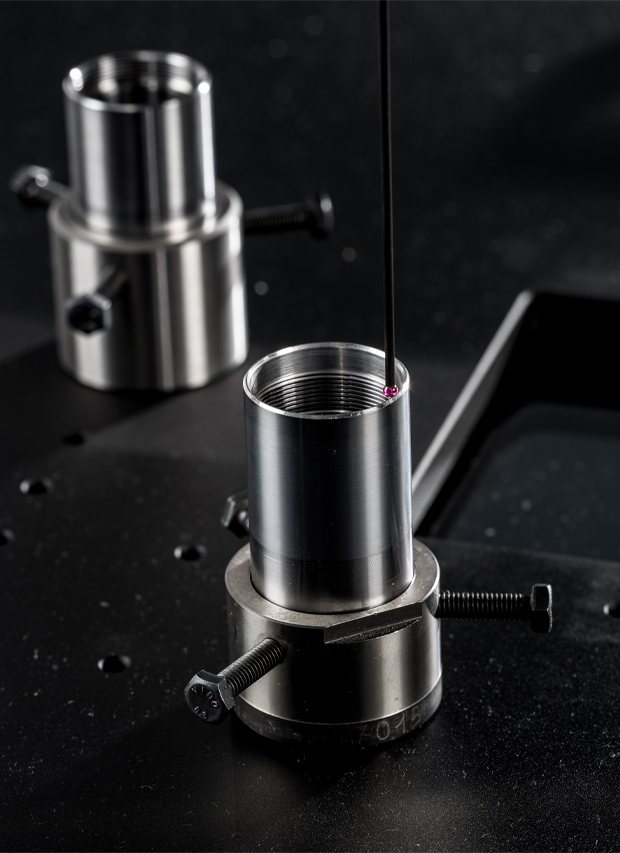

The area dedicated to part checking in the various stages of production ensures quality levels are consistently high, in line with automotive industry standards. The production of especially complex parts is a continuous challenge towards improvement, calling for sophisticated inspection types capable of checking the dimensional conformity of the items produced.

Our laboratory today is in possession of the following inspection equipment of the latest generation, allowing us to support companies with absolutely accurate data:

A relentless drive to seek out new technologies and innovations is a key component of Gi Di Meccanica’s philosophy. The quality system is subject to a process of constant evolution, designed to ensure our clients’ demands can be satisfied in full.