On average, cold forming technology is 100 times faster than turning and far more stable.

The time saving in creating the products and the reduction of scrap make cold forming one of the most efficient and cost effective manufacturing technologies.

The flexibility needed to guarantee a bespoke stamping service is possible thanks to our four decades of know-how and our advanced resources in terms of capital equipment.

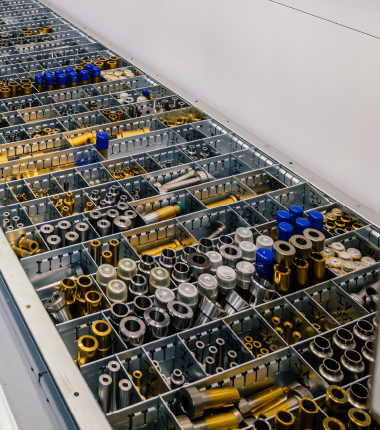

Twenty machines that allow the production of any component required, with in-house construction of every tool we need, from the dies to the milling processes, from dip coating to turning.